Ethernet Based protocol in Industry/ communication protocol in Industry.

In this article we will learn ethernet based communication protocols mainly used in industry for communication in all layers.

In the digital era, Ethernet-based communication protocols are becoming increasingly popular due to their ease of use, high data handling capacity, and ability to provide deterministic communication.

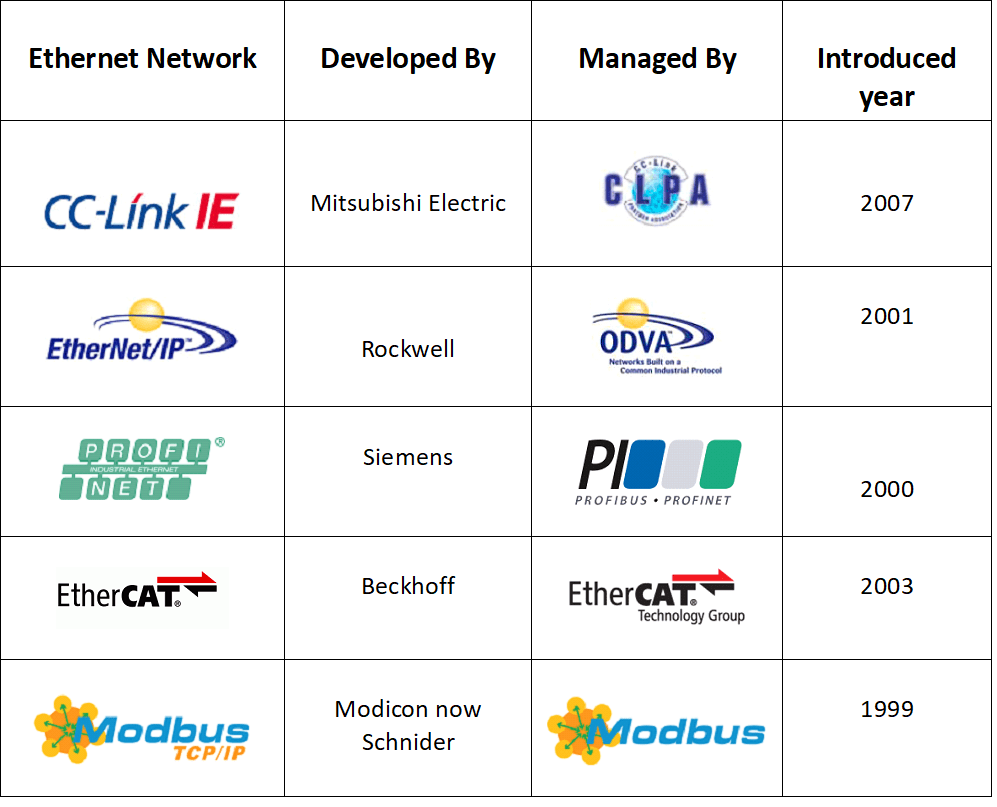

Each major PLC manufacturing company has developed its own communication protocol to interface with field devices and control mechanisms. Below is a list of communication protocols that are widely used in the manufacturing industry.

Advantages of Ethernet based communication protocol

1.Real Time performance:

Rapid Network. Communication speeds in the industry have now even reached 1 Gbps.

2.Large Data Handling Capacity:

Ethernet-based protocols can handle substantial amounts of data, capable of transmitting hundreds of thousands of words of information within milliseconds.

3.Sufficient Bandwidth for control Data and Message Data:

It provides ample bandwidth for both PLC-to-PLC and PLC-to-field device data transmissions.